Vee Rings

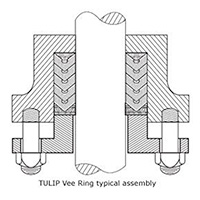

Tulip fabric rubber Vee Rings (chevron packings) are an extremely durable seal. A Vee Ring set is comprised of a series of Vee shaped rings, usually between 3 and 5 per set, supported by a top and bottom adaptor. A Vee Ring set provides a seal in one direction. Back to back sets can be installed to create a double acting seal. The multiple sealing lip construction of a Vee Ring seal creates a gradual breakdown in pressure, reducing the workload of each seal. This creates a long service life and reduces the chance of catastrophic failure of the seal. Prior warning is thus given of possible failure of the set allowing equipment service to be scheduled for off-peak periods. This is especially important when maintenance efficiencies can be improved through planning of machine downtime. Depending upon the gland arrangement, Vee Rings can be adjusted to take up wear, thus further increasing seal life. The adjustment would take the form of a gland nut that allows for periodic tightening.

Tulip manufactures an extensive range of metric and imperial Vee Rings from 4mm through to 2000m in diameter. Seal heights can vary considerably, therefore it is important to know stack heights when ordering. Most glands have sufficient adjustment to allow for a degree of variation.

The below table is a guide for the required number of Vee rings per set for given pressures.

| Seal Cross Section (inch) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 3/16 | 1/4 | 5/16 | 3/8 | 7/16 | 1/2 | 3/4 | 1 | ||

| Recommended number of Vees | 0 - 1000 psi | 3 | 3 | 3 | 3 | 3 | 3 | 4 | 4 |

| 1000 - 3000 psi | 4 | 4 | 4 | 4 | 4 | 4 | 5 | 5 | |

| 3000 - 5000 psi | 5 | 5 | 5 | 5 | 5 | 5 | 6 | 6 | |

| 5000 + psi | 6 | 6 | 6 | 6 | 6 | 6 | 7 | 7 | |

| Lead in Chamfer Length (in.) | 0.10 | 0.10 | 0.15 | 0.15 | 0.20 | 0.20 | 0.25 | ||

Standard Material

Style: T101 Cotton Duck & Synthetic Rubber

Applications:

- Most types of hydraulic presses (main and drawback rams)

- Hydraulic cylinder gland and piston heads

- Hydraulic valves

- Oil pipeline expansion joints

- Homogenisers

- Water, oil, solvents

- Reciprocating and slow rotary applications

- Temperature: -20° to 125°C

- Pressure: Up to 420 Bar (6090 PSI)

- Speed: 3m/s depending on length and frequency of stroke.

Special Material

Style: T221 Kevlar & Synthetic Rubber

Applications:

- Saturated steam, water, oil pumps and valves

- Hot oil reciprocating pumps for refinery duty

- Sludge pumps

- Wash pipe swivels

- Homogenisers

- Water, oil, solvents

- Reciprocating and slow rotary applications

- Temperature: -20° to 180°C

- Pressure: Up to 420 Bar (6090 PSI)

- Speed: 3m/s depending on length and frequency of stroke.

Tulip Corporation Pty Ltd, 1 Apollo Drive, Hallam Victoria 3803 Australia

- Telephone: +61-3-9796 3133

- Fax: +61-3-9796 4933