Custom Mouldings

Whether your requirement is for one part or one million parts, precision components of just a few grams through to large items 50kg plus, Tulip has the expertise and resources to see your project through from concept to final product. With manufacturing plants in Victoria and Thailand we can assist with product design, material selection, prototyping, testing and final production of your part. Our in-house engineering facilities give us the ability to produce moulds quickly and cost effectively.

Reverse engineering of obsolete parts is a specialty of Tulip and can result in the service life of plant and equipment being extended by many years, avoiding or delaying the costs of replacement. Over the years Tulip has developed specialist techniques in fabric reinforcement and bonding of rubber to metals and plastics. In recent years Tulip has also added polyurethane moulding facilities.

- Natural Rubber

- NBR

- EPDM

- Neoprene

- Viton

- Silicone

- Polyurethane

- Hypalon

- Butyl

- Plastics

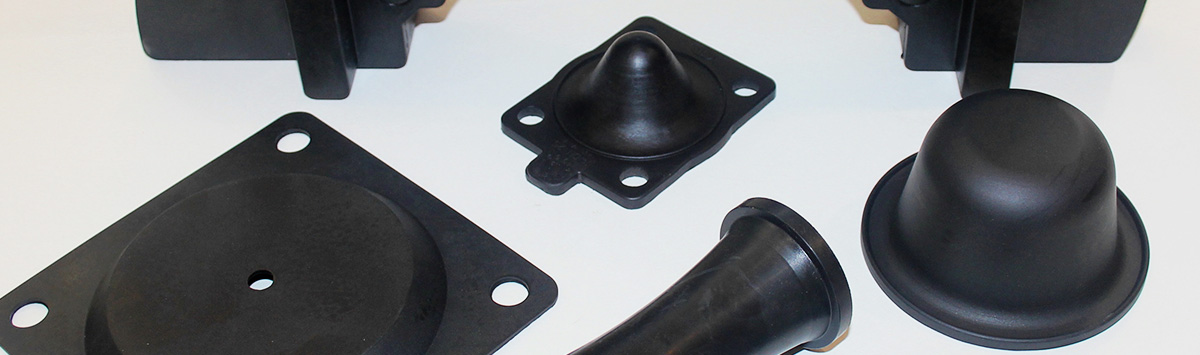

Products examples

- Seals

- Diaphragms

- Resilient mounts

- Pinch valve sleeves

- Manhole gaskets

- High voltage insulators

- Dust boots

- Bellows

- Gaskets

- Buffers

- MRF Screen Discs

Industries

- Manufacturing

- Irrigation

- Power Generation

- Defence

- Transport

- Recycling

- Mining

- Aluminium smelting

- Food & Beverage

- Pharmaceutical

- Hydraulics